PE Tube Production introduction for LissonPackaging

After PE tube is finished, it undergoes rigorous quality control checks to ensure it meets the necessary standards. This includes testing for strength, flexibility, and durability. Any tubes that do not meet the requirements are rejected and recycled.

PE tubes are used in a wide range of applications, including packaging, plumbing, and medical devices. They are valued for their flexibility, chemical resistance, and low cost. The manufacturing process for PE tubes is carefully controlled to ensure the highest quality and consistency in the final product.

Share:

-

PE Tube Production introduction for LissonPackaging

PE Tube Production introduction for LissonPackaging -

LISSON Vibration Eye Cream Tube™ with Eye Lifting Applicator

LISSON Vibration Eye Cream Tube™ with Eye Lifting Applicator -

Lisson Packaging New Plstaic Tube factory

Lisson Packaging New Plstaic Tube factory -

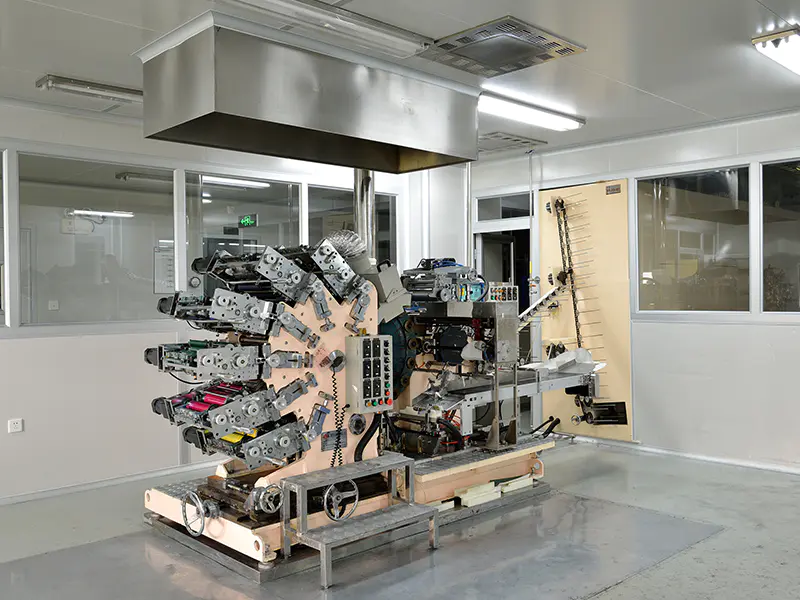

Flexo Graphic Printing Equipment

Flexo Graphic Printing Equipment -

3D Printer Equipment & Printing Process Technology

3D Printer Equipment & Printing Process Technology -

Warmly Celebrate Opening Ceremony Of New Cosmetic Tube Factory

Warmly Celebrate Opening Ceremony Of New Cosmetic Tube Factory -

New arrivals Vibration Massage Bottle for Skincare

New arrivals Vibration Massage Bottle for Skincare -

Sheet Tube Production

Sheet Tube Production -

What's metamorphosis kraft paper tube? Brand new sustainable packaging? Check the video to know more

What's metamorphosis kraft paper tube? Brand new sustainable packaging? Check the video to know more -

Have you heard sugarcane tube? It's new green sustainable packaging, check it in this video-Lisson

Have you heard sugarcane tube? It's new green sustainable packaging, check it in this video-Lisson -

Automatically PE tube extruding machine

Automatically PE tube extruding machine -

High efficiency heading machine for PE tube and Welded tube

High efficiency heading machine for PE tube and Welded tube -

Six colors offset printing machine

Six colors offset printing machine -

Germany imported silk-screen printing machine for welded tube

Germany imported silk-screen printing machine for welded tube -

Customized color and pattern hot stamping machine

Customized color and pattern hot stamping machine -

Left direction labeling machine with whole and partial effect

Left direction labeling machine with whole and partial effect -

Multi-functional Holing/Foil sealing/Cap assembling machine

Multi-functional Holing/Foil sealing/Cap assembling machine -

Automatically positioning and heating sealing machine

Automatically positioning and heating sealing machine -

Final inspection to pick out unqualified products

Final inspection to pick out unqualified products -

-

-

-

-

-

한국의

한국의  Español

Español