Advantages of aluminum plastic cosmetic tube type

by:Lisson

2020-09-11

Cosmetic tube type and application brief introduction

1. Cosmetic tubes are divided into single-layer, double-layer and five-layer cosmetic tubes, which are different in the aspects of anti-pressure, anti-permeability and hand feeling respectively. For example, the five-layer tubes consist of the outer layer, the inner layer, two adhesive layers and another barrier layer.

Features: excellent gas barrier performance, can effectively prevent oxygen and odor gas infiltration, and prevent the content of fragrance and active ingredients from exudation.

2, double-layer tube is more commonly used, the middle and low grade can also be used single-layer, cosmetics tube diameter is 13# - 60# of a variety of caliber, selected for a certain caliber of cosmetics tube, with different length marked different capacity characteristics, capacity of 3ml& AMP;

Ndash lu: su composite tube cosmetics in recent years, the advantages of traditional metal chemical industry, glass containers has been replaced with the lightweight plastic tube cosmetics packaging, investigate its reason, we can find that lu: su composite cosmetics tube has the following advantages: lu: su composite tube cosmetics use convenient health, surface colorful bright, beautiful, therefore it has been widely applied in cream cosmetics packaging, such as cosmetics industry cleanser, hair conditioner, hair dye, toothpaste and other products packaging, as well as the medicine cream, paste the packing of the drugs for external use only, etc.

Aluminum plastic composite cosmetic tube has superior contact performance, and is not easy to break, bright colors, beautiful appearance generous cosmetic tube, the advantages of aluminum plastic cosmetic tube easy to use.

1. Cosmetic tubes are divided into single-layer, double-layer and five-layer cosmetic tubes, which are different in the aspects of anti-pressure, anti-permeability and hand feeling respectively. For example, the five-layer tubes consist of the outer layer, the inner layer, two adhesive layers and another barrier layer.

Features: excellent gas barrier performance, can effectively prevent oxygen and odor gas infiltration, and prevent the content of fragrance and active ingredients from exudation.

2, double tube is relatively common, belongs to the medium can also be single, cosmetics tube diameter for 13 - more than 60 caliber, elected a certain diameter of the tube cosmetics, capacity of different characteristics in different length, capacity of 3 ml - 360 ml can be adjustable, in order to beautiful and coordination, 60 ml below the calibre of the commonly used under 35, 100 ml, 150 ml 35-45 caliber, usually with more than 150 ml capacity is more than 45 #.

3, the process is divided into circular pipe, elliptical pipe, flat pipe, super flat pipe.

Flat tube, super flat tube than other pipe process more complex, is also in recent years out of the new pipe, so the price is correspondingly more expensive.

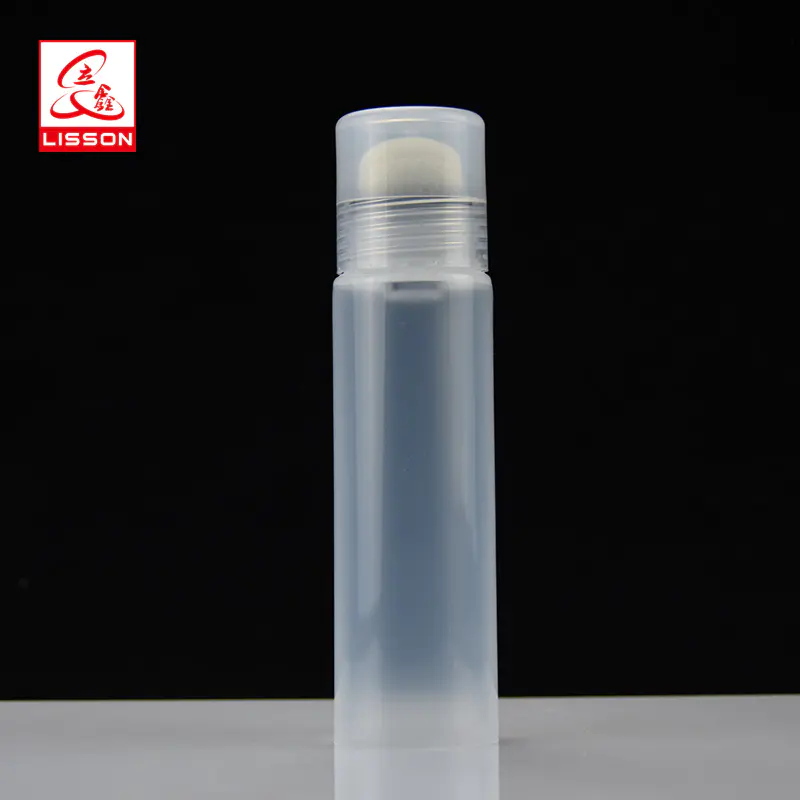

4, cosmetics tube cover shape diversity, generally can be divided into flat head cover, round epicranium, high cover, lift the lid, super flat cover, double cover, the spherical cap, lipstick cover, plastic cover can also be a variety of craft processing, bronzing, silver, non-ferrous cover, transparent, advantages of spray type oil tube cosmetics cosmetics, electroplating, etc., pointed mouth cover and lipstick cover are usually equipped with a plug in.

Cosmetic tube cover for injection products, cosmetic tube for pull tube, most cosmetic tube manufacturers do not produce cosmetic tube cover.

5. Some products need to be filled before sealing. The sealing end can be divided into straight grain sealing end, twill sealing end, umbell-type sealing end, star point sealing end, special-shaped sealing end, and the required date code can be printed at the sealing end.

6, cosmetics tubes can do color tube, transparent tube, color or transparent frosted, bead light pipe, and a dumb light with the light and elegant matte seemingly but easy dirty, colored tube and pipe shaft large difference of printing, but judging from the tail slit, slit for white tube for large area printing, use the ink demand is high, otherwise easy peeling and cracking after folding and white mark.

7, cosmetics tube production cycle is 15 days - 20 days commonly cycle (starting from the confirmation here) order item for 5000-10000, large scale manufacturers usually in 10000 for minimum quantity, if a few small manufacturer variety, item 3000 minimum quantity to also can, there are few customers to open mold, mostly male die (a few characteristics of the lid is the private mold) contract order quantity and actual quantity supplied, the industry of the deviation of plus or minus 10%.

8, cosmetics tube quality and different manufacturers have a big difference in price, plate making fee is usually 200 yuan to 300 yuan price, tube body can be multi-color printing and silk-screen, individual manufacturers have heat transfer printing equipment and technology.

Hot stamping, hot silver to area unit price to calculate, screen printing effect is better, the cost is more expensive and less manufacturers, should be based on different levels of demand to choose different manufacturers.

Custom message

한국의

한국의  Español

Español