D35 100g cosmetic packaging airless pump tube

-

v s

1. The design of Lisson pump tops for bottles takes a lot of effort. The design team devoted a lot of time to market research in the packaging and printing industries. At the same time.

2. The product produces little heat during operation. During the production process, it will be equipped with a substrate with heat dissipation performance, playing a role of cooling.

3. Strong stability is one of its biggest selling points. Its stiles have been laminated to further enhance firmness and toughness.

4. The product does help people save a lot on utility bills. People using this product for 2 years agree that it is really energy efficient.

THE PRODUCT DESCRIPTION

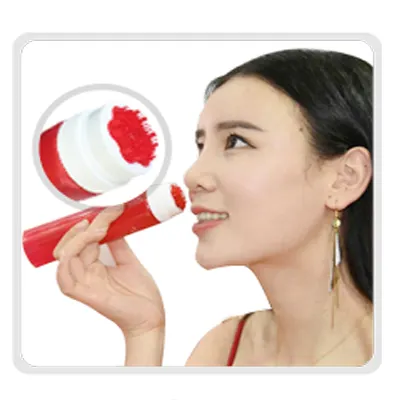

D35 100g cosmetic packaging airless pump tube

The tube can be used for body cream and lotion

The capacity can be 40ml, different capacity meets your different needs

Material can be plastic and alumium,

Printing can be offset/silk screen/hot-stamping

PRODUCT PARAMETERS

Tube Data | |

Products Name | D35 100g cosmetic packaging airless pump tube |

Shape | Round |

Diameter | 35mm |

Tube Length | 156mm |

Material | PE |

Capacity | 100ml |

Tube Color | Customized |

Usage | Used for cream and lotion |

Sealing type | Vertical sealing |

Surface handling | Offset/Slik screen printing/Hot stamping |

Cap Data | |

Material | PP |

Cap Color | Customized |

ADVANTAGE & CUSTOMER PHOTO

The better quality

The implementation of the international quality system, with a professional QC department, all products have undergone strict quality inspection, we abandon the sampling method and spend more manpower and material resources to ensure the quality of the high quality.

The completely products

More than 1000 types of products to meet the diverse needs of customers in different industries, different fields, one-stop service concept.

R & D innovation capacity

With more than 20 patents at home and abroad, with specialized R & D departments and invested sums of money to start production.

The Stronger strength

20000 squares of factory covers, 10 millions output per month, professional production control, first-class equipment manufacturing.

The Higher efficiency

The fastest delivery date is 15 days so that customers can receive the goods in the shortest time, not only the fastest speed , but also the best quality.

APPLICATION

CERTIFICATE

Company Features

1. Lisson has deeply grasped the precious chance to develop.

2. The standard nature of these processes permits us to fabricate pump tops for bottles .

3. Guangzhou Lisson Plastic Co.,Ltd carry forward the goal of airless pump bottles wholesale and conduct a step-by-step airless pump bottles cosmetic . Inquiry! Guangzhou Lisson Plastic Co.,Ltd aims to structure airless tubes cosmetic as its service philosophy. Inquiry! lotion cap has long been a target of Guangzhou Lisson Plastic Co.,Ltd. Inquiry! Guangzhou Lisson Plastic Co.,Ltd adhere to the strategic tenet of airless pumps for cosmetics . Inquiry!